Your Cart is Empty

October 16, 2019 2 min read

How was Structure able to build a full-linkage suspension platform that stands up to the toughest rides and riders while offering a 250-hour bearing service interval?

It's all about thoughtful engineering. Come along for a closer look.

|

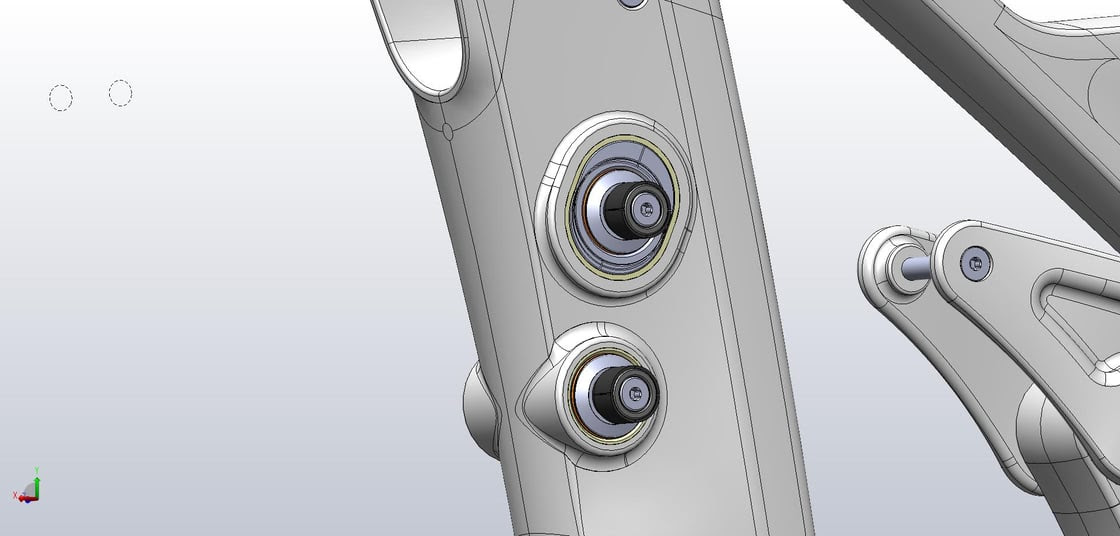

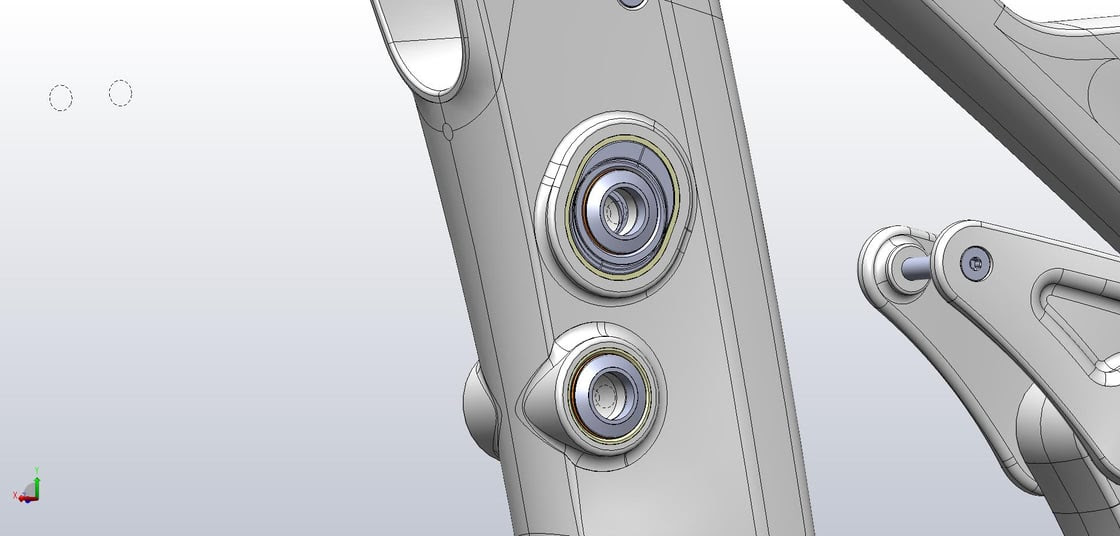

Removal of the front control arms reveals details that make our pivots extremely durable. We start with large, strong, 17 mm collet-type axles.

|

Removal of the axles is simple and gives a view of the bearing caps, which provide precise spacing between suspension arms, bearings, and frame.

|

|

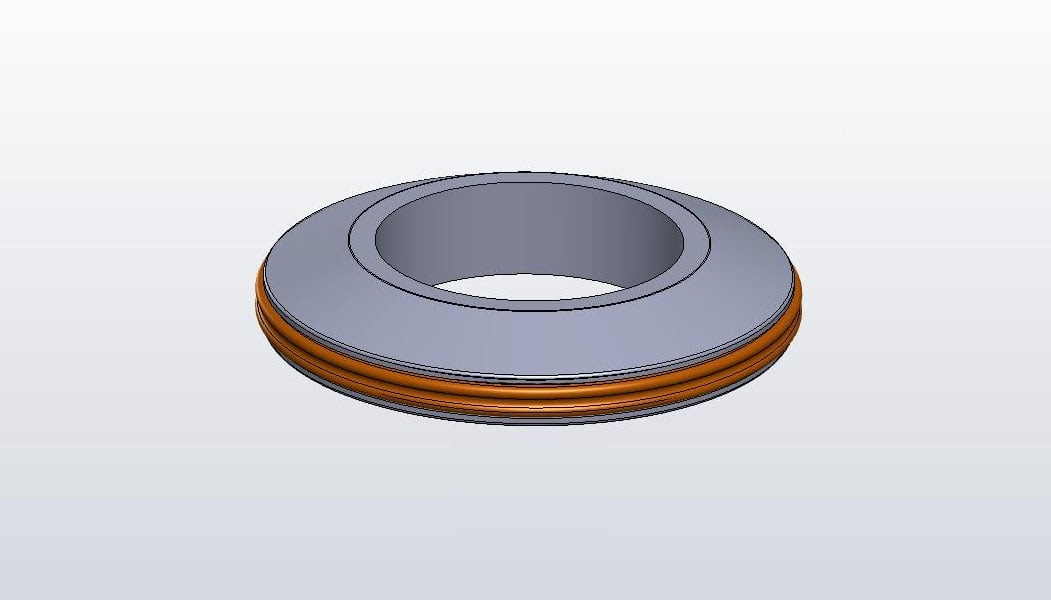

Each of the main bearing caps comes with an x-ring seal to keep water and dust out of the bearings, which is key to bearing longevity. |

|

|

Removal of the 30 mm main pivot bearings reveals alloy through-frame inserts and wide spacing between bearing seats. These features prevent distortion of the pivot system and uneven side-loading of the bearings to increase system stiffness and bearing durability. The eccentric bearing cups (pictured above; 2 sets provided with each bike) of the upper control arm can be installed in one of four positions and reduce brake dive versus telescoping forks by 17%, 22%, 33%, or a whopping 41% to further enhance the stability of our linkage system, which offers the vertical travel equivalent of a 170 mm telescoping fork and 25% greater lateral stiffness.

We built our pivots to last and provide smooth, confidence-inspiring performance for the life of each bike. Last, but certainly not least, anyone who can service rear suspension can easily service a Structure SCW1. Why sweat the smallest details? Because we'd rather be riding than wrenching. Wouldn't you?

Follow us on Instagram at structurecycleworks, and on our new testimonials page, ride_structure to see what real riders are saying after riding the SCW1. |

Comments will be approved before showing up.